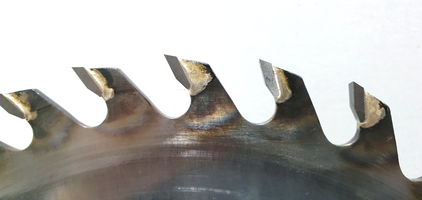

RE-TIPPING - TUNGSTEN CARBIDE TIPPED SAWBLADES

Tungsten tipped (TCT) sawblades require re-tipping after several sharpens due to the teeth wearing thin. Bendigo Saw Sharpening specialises in replacement of Tungsten Carbide teeth, whether this be a part re-tip or a complete re-tip of your sawblade.

Our replacement tips are manufactured using a special grade of carbide designed to give the best performance over the life of the blade. Once re-tipped, sawblades can be re-sharpened several times as the teeth wear during use.

|

|

OUR PROCESS

Re-tipping a Tungsten Tipped (TCT) sawblade is a technical process that can require a lot of skill. With over 25 years experience we have the process mastered to ensure your re-tipped blade performs as new.

Retipping a sawblade involves removing old teeth & tooth fragments, cleaning the saw steel & re-gulleting the sawblade. We then check the level and tension to ensure the blade will run straight and true, and not develop any inconsistency such as wobbling, snaking or shuddering. Once checked, our saw doctors will re-tip the sawblade with new Tungsten Carbide Tips, using a heating process to adhere them to the blade. Once re-tipped the sawblade is ground on our TCT Grinding machines to ensure every tooth is identical. This involves griding the tooth face, tooth top and both sides of the tooth to give the correct angle of relief for the optimum cut and obtain the optimum tooth clearance over the saw steel. Once ground the blades are given a final clean and packaged for collection or dispatch.

FREQUENTLY ASKED QUESTIONS

Some of the teeth on my Sawblade are chipped, should they be replaced?

Tungsten teeth can chip if they hit any hard material in the timber being cut, such as a nail or a stone. When this occurs they will need to be replaced, as attempting to sharpening them will not remove the chip and the blade will continue to perform poorly. Chipped teeth are also prone to fracturing, which can result in them breaking off completely if they continue to be used. This can cause further damage to other teeth on the blade.

How many sharpens should I get before my teeth need to be replaced?

This will depend on factors such as the size of the blade, size & number of teeth on the blade, the type of timber being cut and the cutting conditions. As a general rule if the material being cut is clean and the blade is looked after it can be sharpened multiple times before requiring re-tipping. The life of the tooth will depend on the material being cut, as well as how heavily it is used before it is re-sharpened. A heavily worn tooth will require more grinding to bring the edge sharp, thereby limiting the amount of 'sharpens' that can be done to the tooth.

Some of the teeth on my sawblade are chipped or missing - does my blade need a part-retip or a complete retip?

This will depend on the situation, the size of the blade, the application of the blade and the state of the rest of the teeth. As a general rule of thumb if only a few teeth are missing or damaged it is worthwhile doing a part-retip, especially if the remaining teeth are in perfect condition. However, if a significant amount of teeth are missing it is often just as cost effective to replace them all, due to the time required to match up the new teeth with the existing ones. Other situations requiring a complete re-tip include:

- Where the blade has hit steel or other hard substance and majority of teeth are chipped

- Where the blade has hit steel or other hard substance and fracturing has occurred on a large proportion of teeth (this is difficult to detect)

- Where the blade has been sharpened multiple times and the teeth have become too thin to re-sharpen again

It is best to consult our saw doctors as to what your blade requires when getting it repaired.

For more information or to book your blade in for service, contact us!